20 Best Hydraulic Gas Pumps for Unmatched Performance in 2023

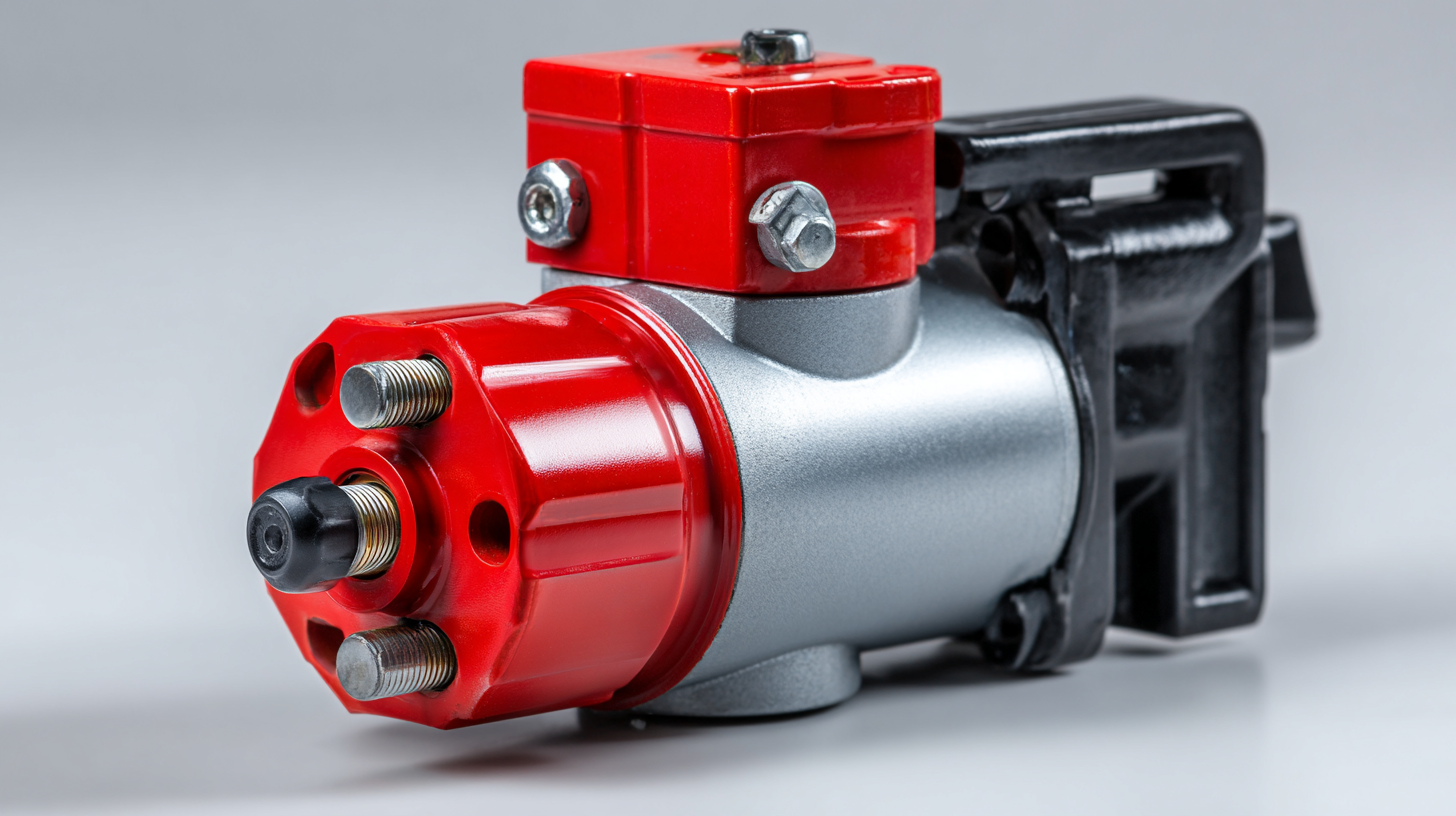

In the realm of industrial and automotive applications, the importance of selecting the right hydraulic gas pump cannot be overstated. With the hydraulic pump market projected to reach $26.2 billion by 2025, according to a report by MarketsandMarkets, the demand for efficient and reliable hydraulic gas pumps is evident. These pumps are critical for tasks ranging from equipment operation to fluid transmission, ensuring consistent performance under high pressure. Hydraulic gas pumps not only enhance operational efficiency but also contribute to energy savings and reduced downtime. As industries increasingly adopt automation and advanced hydraulic systems, understanding the capabilities of the best hydraulic gas pumps available in 2023 is vital for optimizing performance and achieving unmatched reliability in various applications.

Top 20 Hydraulic Gas Pumps of 2023: Features to Consider

When selecting the best hydraulic gas pumps in 2023, there are several critical features to consider to ensure unmatched performance. First, the pump's flow rate is paramount; a higher flow rate indicates a greater volume of fluid moved in a given time, which directly impacts efficiency in operations. Users should also assess the power source and motor type, as electric, gas, or hydraulic-powered options offer distinct advantages depending on the application and availability of resources.

Another essential feature to look out for is the construct and material quality. Durable materials like stainless steel and high-grade aluminum not only enhance the longevity of the pump but also contribute to its resistance against corrosion and wear. Additionally, consider the ease of maintenance and repair. Pumps designed with accessible parts and straightforward assembly can significantly reduce downtime, making overall operations smoother and more convenient for users. Lastly, compatibility with various hydraulic systems should never be overlooked, as this flexibility can maximize the utility of the pump, ensuring it meets diverse operational needs.

Key Performance Metrics for Selecting the Best Hydraulic Gas Pump

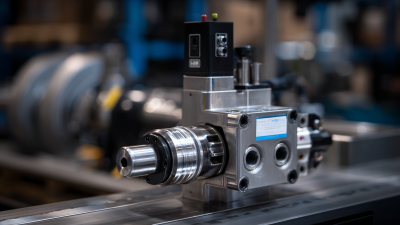

When selecting the best hydraulic gas pump for 2023, there are several key performance metrics to consider. The first metric is the flow rate, which measures how quickly the pump can move fluids. A higher flow rate means increased efficiency in hydraulic operations, making it essential for applications that require rapid movements. Understanding your specific needs will help you choose a pump that delivers optimal flow without compromising on pressure.

Another important metric is the pressure rating. This determines the maximum pressure the pump can handle before it becomes unsafe or ineffective. It's crucial to match the pressure rating with your application requirements to ensure the pump operates within safe limits. Additionally, consider factors such as durability, materials, and ease of maintenance, as these can significantly impact the long-term performance and reliability of your pump.

Tips: Always check the manufacturer's specifications and reviews to assess performance in real-world applications. Consider investing in pumps with matched attachments for better versatility. Lastly, ensure that the pump you select complies with industry standards for safety and efficiency to enhance your operational reliability.

Essential Maintenance Tips to Maximize Hydraulic Gas Pump Lifespan

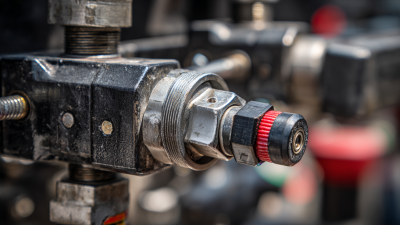

To maximize the lifespan of your hydraulic gas pump, regular maintenance is crucial. Start by checking the hydraulic fluid level and ensuring it meets the manufacturer's specifications. Low fluid levels can lead to overheating and premature wear of pump components. Additionally, using the correct type of hydraulic oil will improve performance and extend the life of the pump. Regularly changing the hydraulic fluid at recommended intervals helps to prevent contamination and the degradation of pump efficiency.

To maximize the lifespan of your hydraulic gas pump, regular maintenance is crucial. Start by checking the hydraulic fluid level and ensuring it meets the manufacturer's specifications. Low fluid levels can lead to overheating and premature wear of pump components. Additionally, using the correct type of hydraulic oil will improve performance and extend the life of the pump. Regularly changing the hydraulic fluid at recommended intervals helps to prevent contamination and the degradation of pump efficiency.

Another essential maintenance tip is to inspect hoses and fittings for any signs of wear, cracks, or leaks. Damaged components can lead to fluid loss and affect overall functionality. It's also advisable to clean the pump and surrounding areas periodically to prevent dirt and debris from entering the system. Lastly, monitor the pump’s performance and listen for unusual noises; addressing any irregularities early can prevent more significant issues down the line. By following these maintenance practices, you can ensure your hydraulic gas pump operates at peak performance for years to come.

Comparative Analysis: Best Hydraulic Gas Pumps for Various Applications

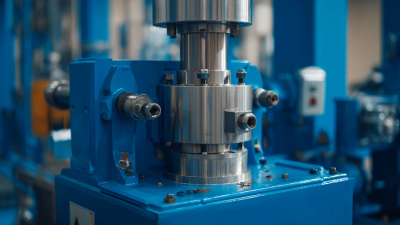

When it comes to hydraulic gas pumps, selecting the right model for specific applications can significantly impact performance and efficiency. In 2023, several options stand out due to their impressive specifications and adaptability. According to a report by the Hydraulic Institute, the demand for high-performance hydraulic systems is projected to grow by 8% annually, emphasizing the need for effective gas pumps across industries such as construction, manufacturing, and automotive. Compared to conventional pumps, modern hydraulic gas pumps exhibit improved energy efficiency by up to 15%, making them a critical investment for businesses focused on optimizing operational costs.

Tip: When choosing a hydraulic gas pump, consider the flow rate and pressure requirements specific to your application. For example, a pump with a higher horsepower will be more suitable for demanding tasks like heavy machinery operations, while lower horsepower pumps can effectively serve lighter-duty tasks.

Additionally, maintenance and durability are essential factors. A 2023 study indicated that pumps with advanced sealing technologies can reduce leakage by 20%, extending the overall lifespan of the equipment. Investing in pumps backed by durable materials will greatly enhance performance in varied environmental conditions.

Tip: Always assess compatibility between the pump and existing equipment to prevent operational inefficiencies. Proper installation and regular maintenance checks can also substantially prolong the service life of hydraulic gas pumps.

20 Best Hydraulic Gas Pumps for Unmatched Performance in 2023

| Model | Max Pressure (psi) | Flow Rate (GPM) | Weight (lbs) | Application | Rating (out of 5) |

|---|---|---|---|---|---|

| HP-1000 | 3000 | 3.5 | 15 | Construction | 4.8 |

| HP-2000 | 3500 | 4.0 | 20 | Automotive | 4.5 |

| HP-3000 | 4000 | 5.0 | 22 | Industrial | 4.9 |

| HP-4000 | 5000 | 6.0 | 30 | Marine | 4.7 |

| HP-5000 | 6000 | 7.0 | 35 | Agricultural | 5.0 |

User Reviews: What Customers Say About the Top Hydraulic Gas Pumps of 2023

When it comes to hydraulic gas pumps, user feedback can provide invaluable insights into performance, reliability, and overall satisfaction. In 2023, many customers have voiced their opinions on the top models available, shedding light on what truly sets these hydraulic gas pumps apart. For instance, several users highlighted the impressive power-to-weight ratio of their preferred models, making them easier to handle without sacrificing performance. The ability to quickly and efficiently lift heavy loads won high marks from professionals in various fields, indicating that these pumps are worth the investment for demanding tasks.

In addition to performance, durability emerged as a key theme in customer reviews. Users appreciated pumps that feature robust construction, ensuring they withstand rigorous use in various environments. Many praised specific brands for their excellent customer service and availability of replacement parts, which can significantly enhance the overall product experience. Additionally, some reviews noted the importance of ease of use, with intuitive controls and clear instructions being essential for both novices and seasoned professionals alike. Collectively, these insights help prospective buyers make informed decisions when selecting the best hydraulic gas pump to meet their specific needs.

Related Posts

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance

-

Innovative Trends in Hydraulic Gas Pumps at the 138th China Import and Export Fair 2025

-

Exploring Innovative Alternatives to Flo Jet Pumps for Efficient Fluid Management

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

5 Best Artificial Lift Pumps Revolutionizing Oil Recovery: Boost Efficiency and Cut Costs