7 Essential Tips for Choosing the Right Hydraulic Oil Pump for Your Needs

When it comes to ensuring optimal performance and longevity of your machinery, selecting the right hydraulic oil pump is crucial. Hydraulic oil pumps play a pivotal role in fluid power systems, converting mechanical energy into hydraulic energy to drive various applications. However, with the plethora of options available in the market, choosing the right hydraulic oil pump can be a daunting task. This article aims to simplify the decision-making process by providing seven essential tips that will guide you in selecting a hydraulic oil pump that suits your specific needs.

Understanding the key factors that influence hydraulic pump performance can significantly enhance your operational efficiency and reduce maintenance costs. Each application has unique requirements regarding flow rate, pressure capacity, and compatibility with the hydraulic fluid. Therefore, it is essential to evaluate your system's specifications and operational environment before making a purchase. In the following sections, we will delve into actionable tips that address these considerations, making it easier for you to navigate through the complexities of choosing a hydraulic oil pump effectively.

Understanding Different Types of Hydraulic Oil Pumps and Their Applications

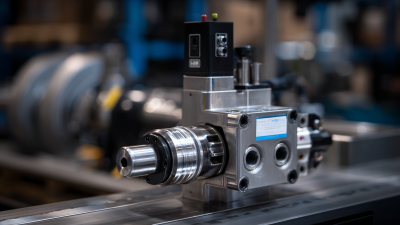

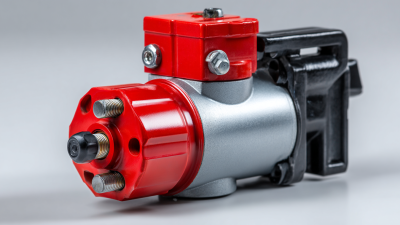

When selecting a hydraulic oil pump, it's crucial to understand the different types available and their specific applications. Common types of hydraulic pumps include gear pumps, piston pumps, and vane pumps.

Gear pumps are known for their simplicity and reliability, making them ideal for low-pressure applications where consistent flow is required.

On the other hand, piston pumps are preferred for high-pressure systems due to their efficiency and ability to handle variable flow rates, which makes them suitable for heavy machinery and industrial use.

Vane pumps strike a balance between performance and cost, often used in mobile applications like construction equipment. These pumps can deliver moderate pressure efficiently and are versatile enough to work in various environments.

It's essential to consider factors such as the required pressure, desired flow rate, and the working environment when choosing a hydraulic pump.

By understanding these different types and their applications, you can make a more informed decision that aligns with your specific needs.

Key Factors to Consider When Assessing Pump Flow Rate Requirements

When choosing the right hydraulic oil pump, assessing the flow rate requirements is crucial. Flow rate directly impacts the efficiency and effectiveness of the pumping system in various applications. For instance, in industrial manufacturing settings, low flow rate pumps typically cater to smaller operations requiring precise control, while high flow rate pumps are essential for large-scale projects with significant volume demands. Recent market analyses indicate that the portable air sampling pump market is experiencing a surge, particularly in the low flow rate segment, driven by increasing environmental regulations and a growing emphasis on air quality monitoring.

Moreover, as industries increasingly adopt advanced technologies, the integration of innovative approaches, such as deep learning, has revolutionized energy consumption modeling in wastewater pumping systems. By employing advanced algorithms, these systems can optimize performance, thereby ensuring that energy use aligns closely with demand. This shift not only enhances operational efficiency but also contributes to more sustainable practices in managing hydraulic systems. Understanding these dynamics is vital for making informed decisions about hydraulic oil pumps that best suit your operational needs.

The Importance of Viscosity and Temperature Ratings in Hydraulic Oil Selection

When selecting the right hydraulic oil pump, understanding the significance of viscosity and temperature ratings is crucial. Viscosity refers to the thickness of the hydraulic fluid and its ability to flow under specific conditions. According to the Hydraulic Institute, the optimal viscosity ensures efficient operation, reducing friction and wear on the pump components. For instance, a high viscosity fluid can provide better lubrication but may cause cavitation at lower temperatures, while a low viscosity fluid may result in insufficient lubrication at elevated temperatures.

Temperature ratings also play a vital role in hydraulic oil selection. The American Society for Testing and Materials (ASTM) highlights that hydraulic fluids must operate within specific temperature ranges to maintain their performance levels. Most hydraulic oils are rated for operation between -20°C to 80°C; however, high-performance synthetic oils can withstand broader temperature fluctuations. Choosing a hydraulic oil that matches the specific temperature requirements of the application can prevent potential breakdowns and prolong the lifespan of the hydraulic system. Ultimately, aligning both viscosity and temperature ratings with the operational demands of your machinery will enhance efficiency and reliability in hydraulic applications.

Evaluating Pump Materials and Construction for Longevity and Performance

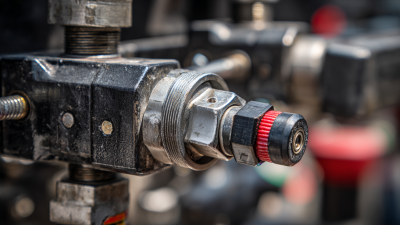

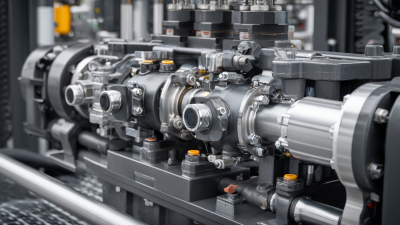

When selecting a hydraulic oil pump, evaluating the materials and construction is crucial for ensuring longevity and optimal performance. The choice of materials directly affects the pump's durability and resistance to wear, corrosion, and pressure variations. For instance, pumps constructed from high-quality steel or stainless steel offer superior strength and longevity, making them suitable for demanding environments. Additionally, the surface treatments applied to these materials can enhance their resistance to environmental factors, such as moisture and chemicals, further extending the pump’s lifespan.

Moreover, the construction method employed during manufacturing plays a significant role in the pump's reliability. Welded joints are generally stronger than bolted ones, providing enhanced structural integrity. Look for pumps that feature precision machining processes, as they tend to provide better fit and finish, reducing the likelihood of leaks and mechanical failures. The design should also allow for easy maintenance; features such as accessible ports for servicing or replaceable components can significantly improve the pump's operational efficiency over time. By focusing on high-quality materials and robust construction, you can ensure that your hydraulic oil pump will meet performance expectations and withstand the rigors of daily use.

7 Essential Tips for Choosing the Right Hydraulic Oil Pump for Your Needs

| Tip | Description | Importance | Material Considerations |

|---|---|---|---|

| 1. Assess Your Requirements | Analyze the specific needs based on your system's demands. | High | Opt for materials that suit your application environment. |

| 2. Consider Pump Type | Evaluate which pump type best suits your operation (gear, vane, piston). | Medium | Different types require different materials for optimal performance. |

| 3. Evaluate Flow Rate | Match the pump’s flow rate to your system to ensure efficiency. | High | Material must withstand required flow without degradation. |

| 4. Check Pressure Rating | Ensure the pump's pressure rating aligns with your system needs. | High | Construction materials should handle the required pressure safely. |

| 5. Research Maintenance Requirements | Understand how much maintenance you are willing to perform. | Medium | Certain materials may require more frequent maintenance. |

| 6. Look at Efficiency Ratings | Choose pumps known for their energy efficiency to reduce costs. | High | Materials that enhance efficiency often lead to longer service life. |

| 7. Verify Compatibility with Fluids | Ensure the pump materials are compatible with the hydraulic fluids used. | High | Material selection is crucial to avoid chemical reactions that damage the pump. |

Choosing Between Fixed and Variable Displacement Pumps for Your System Needs

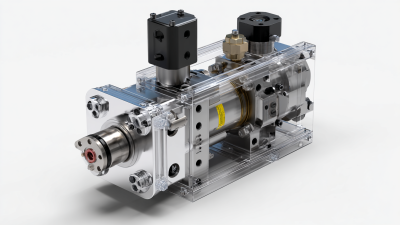

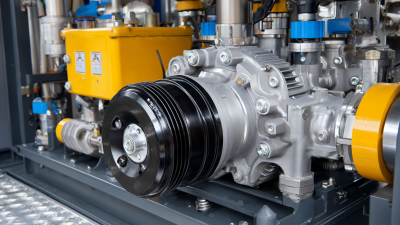

When selecting a hydraulic oil pump, understanding the difference between fixed and variable displacement pumps is crucial for optimizing system performance. Fixed displacement pumps provide a constant flow rate, making them ideal for applications where consistent hydraulic power is necessary. These pumps are simpler in design and often more reliable for straightforward tasks, as they operate at a predetermined flow and pressure. They are particularly suitable for systems with a steady load and can help reduce energy consumption in processes where fluctuating demands are minimal.

On the other hand, variable displacement pumps offer versatility by allowing the flow rate to adjust according to the demands of the system. This adaptability is vital in applications where loads vary significantly, as it enables efficient energy use and reduces wear on hydraulic components. Variable displacement pumps can respond to real-time changes in pressure and flow requirements, providing better control and system efficiency. Choosing between these two types of pumps ultimately depends on the specific operational needs, including load variability, efficiency requirements, and the complexity of maintenance the system can accommodate.

Related Posts

-

Why Choose a Hydraulic Oil Pump: Key Benefits and Features Explained

-

How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

20 Best Hydraulic Gas Pumps for Unmatched Performance in 2023

-

Unlocking Efficiency: How Hydraulic Gas Pumps Revolutionize Industrial Applications

-

Understanding the Importance of Hydraulic Pumps in Modern Industrial Applications