Why Frac Pumps Are Essential for Maximizing Hydraulic Fracturing Efficiency

In the ever-evolving landscape of hydraulic fracturing, frac pumps have emerged as a critical component for enhancing operational efficiency and maximizing recovery rates. Recent industry reports indicate that the demand for hydraulic fracturing is set to grow at a compound annual growth rate (CAGR) of approximately 5% from 2023 to 2030, underscoring the need for reliable and powerful frac pumps in this sector. As per the Energy Information Administration (EIA), efficient frac pump systems can lead to a staggering 20% increase in production outputs by optimizing fluid delivery and managing pressure effectively. The capabilities of modern frac pumps not only streamline the fracturing process but also contribute to overall cost reduction, making them indispensable for operators aiming to improve their return on investment. Given the significant role that frac pumps play, understanding their mechanics and advancements is essential for stakeholders seeking to capitalize on the burgeoning opportunities within the hydraulic fracturing industry.

The Importance of Frac Pumps in Hydraulic Fracturing Operations

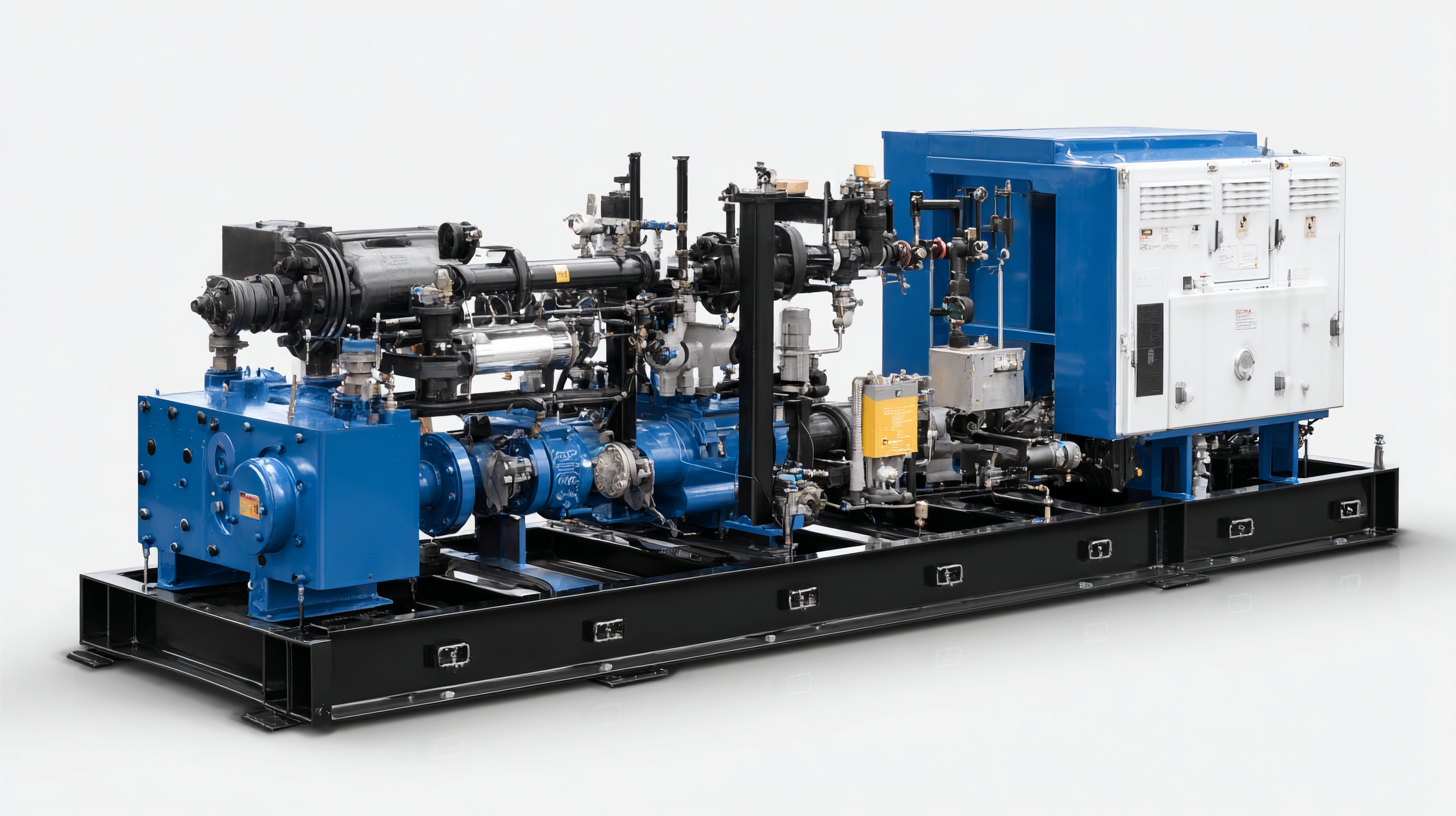

In hydraulic fracturing operations, frac pumps play a pivotal role in maximizing efficiency and enabling the effective extraction of hydrocarbons from shale and other tight formations. These pumps are designed to inject large volumes of frac fluid at high pressures, creating fractures within the rock, which allows oil and natural gas to flow more freely to the surface. The reliability of these pumping systems is crucial, as any failure could result in significant downtime and loss of production, underscoring the importance of maintaining and upgrading equipment as technology advances.

Tips: When selecting frac pumps for your operations, consider the pumping capacity and pressure rating to ensure they meet your specific field conditions. Regular maintenance checks can help prevent unexpected breakdowns, allowing you to optimize your hydraulic fracturing processes more effectively.

As the hydraulic fracturing industry continues to innovate, advancements in dual-engine systems are set to propel operational efficiency even further. Such innovations not only improve the pumping capabilities but also address environmental concerns associated with fracking. By adopting greener technologies and practices, companies can fulfill regulatory requirements while maintaining production levels, reflecting a shift towards more sustainable operations in the industry.

Tips: Stay informed about emerging technologies in the hydraulic fracturing sector to ensure your operations leverage the latest advancements, which can lead to significant cost savings and improved output. Regular training for personnel on the newest equipment and techniques can further enhance operational proficiency.

Key Components of Frac Pumps That Enhance Performance

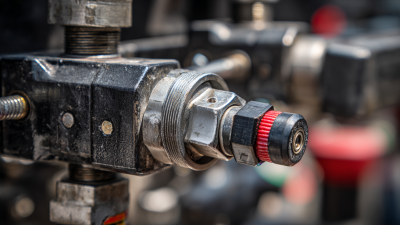

Frac pumps are critical to the hydraulic fracturing process, and understanding their key components can significantly enhance their performance in the field. One of the primary elements involved in frac pump efficiency is the bearing system. Bearings, whether they are ball or roller types, play a vital role in supporting the pump’s rotor while minimizing friction and wear, thus ensuring longevity and reliability under high-pressure conditions.

Industry reports indicate that the global vacuum pump bearing market is expected to witness substantial growth, driven by advancements in bearing materials such as steel and ceramic, which can withstand harsh operating environments typical in hydraulic fracturing.

Additionally, the materials used in manufacturing frac pump components directly impact their operational efficiency. For instance, the integration of advanced materials reduces maintenance requirements and enhances overall pump performance. As the industry continues to evolve, data suggests that innovations in bearing design and materials could lead to a significant increase in hydraulic fracturing productivity. With a projected rise in demand for frac pumps, understanding these key components will be essential for operators looking to maximize efficiency and reduce costs in their fracturing operations.

How Frac Pumps Improve Fluid Delivery Efficiency

Hydraulic fracturing, or fracking, heavily relies on frac pumps to ensure the efficient delivery of fluids into the wellbore. These specialized pumps are designed to handle high-pressure operations and maintain a consistent flow rate, which is critical for successful fracturing. According to a report by the U.S. Energy Information Administration, optimizing fluid delivery can lead to a significant increase in overall well productivity, enhancing the economics of extraction. Proper management of frac pumps can reduce fluid variances that compromise formation integrity.

Moreover, industry studies indicate that advancements in frac pump technology have increased fluid delivery efficiency by up to 15% compared to traditional systems. The implementation of real-time monitoring technologies and automated controls in frac pumps allows operators to adjust parameters instantaneously, minimizing downtime and maximizing resource recovery. A report by the Society of Petroleum Engineers suggests that enhanced fluid delivery not only improves fracturing efficacy but also contributes to reducing operational costs—making it essential for companies aiming to stay competitive in the evolving energy landscape.

The Role of Frac Pumps in Reducing Fracturing Costs

Frac pumps play a pivotal role in hydraulic fracturing operations by efficiently delivering high volumes of water, proppants, and chemicals under pressure to fracture formations deep in the earth. According to a report by the U.S. Energy Information Administration (EIA), hydraulic fracturing has enabled a significant increase in U.S. natural gas production, contributing to a more than 50% increase in U.S. natural gas output over the last decade. The efficiency of frac pumps directly correlates with operational costs, as they impact the speed and effectiveness of the fracking process.

By optimizing the use of frac pumps, companies can considerably reduce fracturing costs. A study from the Society of Petroleum Engineers (SPE) reveals that optimizing frac pump performance can lead to a cost reduction of up to 25%, significantly enhancing the economic viability of shale gas plays. Additionally, advancements in pump technology have improved reliability and reduced maintenance downtime, which further contributes to lower overall project expenses. Therefore, investing in high-quality frac pumps not only ensures operational efficiency but also plays a critical role in maximizing returns on investment in hydraulic fracturing projects.

Why Frac Pumps Are Essential for Maximizing Hydraulic Fracturing Efficiency - The Role of Frac Pumps in Reducing Fracturing Costs

| Parameter | Value | Significance |

|---|---|---|

| Pump Pressure (psi) | 5,000 | Higher pressure can enhance fracture depth and connectivity. |

| Flow Rate (bpm) | 70 | Optimum flow rate ensures effective fluid delivery to the formation. |

| Operational Cost ($/frack) | 150,000 | Cost-saving measures can enhance profit margins in the long run. |

| Water Usage (bbl) | 15,000 | Efficient water management can reduce environmental impact. |

| Fracture Network Efficiency (%) | 85 | Higher efficiency helps in maximizing resource recovery. |

Technological Innovations in Frac Pump Design for Enhanced Efficiency

Hydraulic fracturing, commonly known as fracking, relies heavily on frac pumps to ensure optimal efficiency during the extraction process. Recent innovations in frac pump design emphasize high pressure and flow rates, allowing operators to deliver water and proppants effectively into the wellbore. The latest data from the Energy Information Administration (EIA) indicates that improved pump technologies can boost fracturing efficiency by up to 30%, significantly reducing operational costs and enhancing resource extraction.

One notable advancement is the integration of electric frac pumps, which provide a cleaner alternative to traditional diesel-powered machines. According to a report by the American Petroleum Institute (API), electric pumps not only reduce emissions by approximately 45% but also facilitate quieter operations, making sites more compliant with local regulations. This shift is crucial as companies strive to meet environmental standards while maximizing output.

Tips for operators include regularly scheduled maintenance checks on frac pumps to prevent costly downtimes and ensure peak performance. Additionally, investing in real-time monitoring systems can help track pump efficiency and detect issues before they escalate, allowing for immediate corrective actions. Embracing these technological innovations not only fosters operational efficiency but also positions companies as leaders in the evolving oil and gas sector.

Related Posts

-

How to Select the Right Fracking Pump for Your Oil and Gas Operations

-

Ultimate Guide to Fracking Pump Maintenance Checklist for Optimal Performance

-

How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance

-

5 Essential Tips for Choosing the Right Surface Jet Pump for Your Needs

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

Streamlining Efficiency: Innovative Solutions for Gas Well Pump Operations in Oil and Gas Industry