Understanding the Role of Fracking Pumps in Modern Oil Extraction Techniques

In the realm of modern oil extraction techniques, fracking pumps play a pivotal role in facilitating the hydraulic fracturing process that has transformed the energy sector. According to a report by the U.S. Energy Information Administration, U.S. crude oil production reached unprecedented levels, driven largely by advancements in extraction technologies, including the use of high-capacity fracking pumps.

These sophisticated pumps are engineered to inject water, sand, and additives into rock formations at high pressures, enabling the release of hydrocarbons trapped deep within the earth. The efficiency and reliability of fracking pumps have not only enhanced extraction rates but also significantly lowered production costs, making oil extraction from shale formations economically viable. As the industry continues to evolve, understanding the intricate mechanisms and operational nuances of fracking pumps will be essential for maximizing output and optimizing resource management in the quest for sustainable energy solutions.

Overview of Fracking Pumps and Their Functionality in Oil Extraction

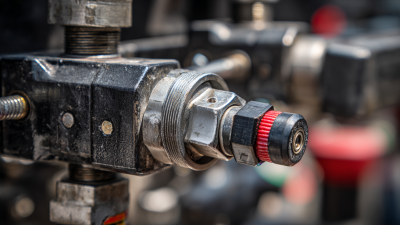

Fracking pumps play a crucial role in modern oil extraction techniques, specifically in hydraulic fracturing. These specialized pumps are designed to inject fluid into deep underground rock formations at high pressures, creating fractures that allow oil and gas to flow more freely toward the surface. The functionality of fracking pumps is not just about force; they must also be able to manage a variety of fluids, including water, sand, and specific chemicals that enhance the extraction process. The intricate design of these pumps ensures they can withstand the extreme conditions encountered during fracturing operations, including high pressures and abrasive materials.

Furthermore, the efficiency of fracking pumps directly impacts the overall productivity of oil fields. Advanced technologies, such as variable-speed drives and real-time monitoring systems, have revolutionized how these pumps operate. By optimizing pressure and flow rates, operators can maximize the amount of hydrocarbons extracted while minimizing the environmental impact associated with fracking. As the industry continues to evolve, the innovation within fracking pump technology remains pivotal, balancing the demands of economic viability and environmental responsibility in oil extraction.

Types of Fracking Pumps Used in Modern Extraction Techniques

Fracking pumps play a crucial role in modern oil extraction techniques, ensuring that the high-pressure fluids are effectively delivered into the subterranean reservoirs. There are primarily three types of fracking pumps utilized in the industry: positive displacement pumps, centrifugal pumps, and triplex pumps. Each type serves specific operational needs and is selected based on factors such as the depth of the well, the viscosity of the fracking fluid, and the required flow rates.

Positive displacement pumps are widely used due to their ability to handle highly viscous fluids and maintain constant flow rates regardless of pressure changes. According to a recent report by the U.S. Energy Information Administration, about 80% of fracking operations utilize positive displacement pumps for their reliability and efficiency. On the other hand, centrifugal pumps, while less common in hydraulic fracturing, are sometimes used in less demanding applications due to their high flow rates and moderate pressure capabilities. Triplex pumps, known for their durability and ability to handle high pressures, are also favored in complex fracking operations. These pumps are often engineered to deliver pressures exceeding 15,000 psi, enabling more effective fracturing of dense rock formations.

Innovations in pump technology continue to enhance fracking performance. The market for fracking pumps is projected to grow at a CAGR of over 7% through 2025, driven by the increasing domestic production of oil and gas. This growth underscores the importance of selecting the right type of pump for specific fracking operations, optimizing both efficiency and cost-effectiveness in the extraction process.

Key Technologies Enhancing Fracking Pump Efficiency and Performance

Fracking pumps play a crucial role in modern oil extraction, significantly influencing efficiency and operational performance. Key advancements in pump technology have led to notable improvements in fracking operations. According to a report from the International Energy Agency (IEA), the effective use of high-pressure pumps has enhanced resource recovery rates by up to 30%, ensuring that more hydrocarbons are extracted from shale formations. This increase in efficiency not only maximizes output but also reduces operational costs, allowing companies to better compete in a volatile market.

Moreover, the integration of computerized control systems has revolutionized pump performance, optimizing flow rates and enhancing safety protocols. Studies indicate that real-time data analytics can reduce pump failures by as much as 40% by enabling predictive maintenance strategies. A report from Research and Markets highlights that the global fracking pump market is expected to grow at a CAGR of 5.2% through 2025, driven by these technological advancements. As the industry continues to evolve, fracking pumps remain at the forefront, directly impacting the success of oil extraction efforts around the world.

Environmental Considerations and Challenges Associated with Fracking Pumps

Fracking, or hydraulic fracturing, is a critical method for extracting natural gas and oil from deep rock formations, but it is not without its significant environmental concerns. The process involves injecting high-pressure fluid into underground rock, which can lead to polluted waterways, habitat destruction, and adverse effects on wildlife. Notably, a report from the Environmental Protection Agency indicates that 90% of the water used in fracking can return to the surface contaminated with various toxic substances, thereby posing risks to local ecosystems and drinking water supplies.

In light of these challenges, the industry's expansion raises serious questions about sustainability. As former Pennsylvania environmental protection chief David Hess notes, fracking remains a top concern, calling for stricter regulations and more responsible management practices. Moreover, there is growing anxiety about the effects of pumping carbon dioxide underground, which can potentially induce earthquakes similar to those associated with fracking operations, highlighting the need for comprehensive environmental assessments and monitoring.

Tips for mitigating the environmental impacts of fracking include:

- Implementing advanced filtration systems to reduce water contamination.

- Developing regulations that require the recycling of fracking water to minimize waste.

- Investing in research to identify less invasive extraction techniques that could lessen habitat disruption.

Future Trends in Fracking Pump Innovations and Their Impact on Oil Production

As the oil extraction industry evolves, the role of fracking pumps is becoming increasingly significant. Future trends indicate that innovations in fracking pump technology will optimize hydrocarbon recovery and enhance sustainability practices. According to a report by the International Energy Agency (IEA), advancements in pump materials and designs can lead to a 20% improvement in efficiency, reducing both operational costs and environmental impact. The integration of smart technologies, such as IoT sensors, is set to revolutionize real-time monitoring and predictive maintenance, minimizing downtime and maximizing production.

Tip: When considering new fracking pump technologies, it's important to assess the compatibility with existing systems to ensure seamless integration and optimal performance.

Looking ahead, the market is expected to see a rise in electric fracking pumps, which can reduce greenhouse gas emissions by up to 45% compared to traditional diesel-powered units. This shift not only aligns with global emissions reduction targets but also reflects a growing demand for greener extraction methods from stakeholders. Investing in these technologies could significantly enhance operational efficiency and meet regulatory requirements more effectively.

Tip: Always evaluate the long-term benefits of transitioning to electric fracking pumps, including potential savings on fuel costs and the value of meeting sustainability goals.

Related Posts

-

How to Select the Right Fracking Pump for Your Oil and Gas Operations

-

Ultimate Guide to Fracking Pump Maintenance Checklist for Optimal Performance

-

How to Choose the Right Water Well Pump for Your Home Needs

-

How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance

-

Exploring Innovative Alternatives to Flo Jet Pumps for Efficient Fluid Management

-

7 Best Practices to Maximize Efficiency of Your Well Pressure Pump