Why Industrial Pumps Are Essential for Efficient Process Engineering in Manufacturing Industries

In the realm of manufacturing industries, the significance of industrial pumps cannot be overstated, as they play a pivotal role in ensuring efficient process engineering. According to a report by the MarketsandMarkets Research, the global industrial pump market is projected to reach USD 75.32 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.6% from 2020 to 2025.

This growth underscores the critical need for reliable fluid movement solutions in various applications, from water supply and wastewater treatment to chemical processing and food production. Industrial pumps are essential not only for maintaining operational efficiency but also for meeting increasing regulatory demands and sustainability goals. By optimizing the transportation of fluids, manufacturers can enhance productivity, reduce energy consumption, and minimize downtime, paving the way for a more resilient and competitive industry landscape.

Thus, understanding the significance of industrial pumps is imperative for any stakeholder aiming to thrive in the dynamic manufacturing environment.

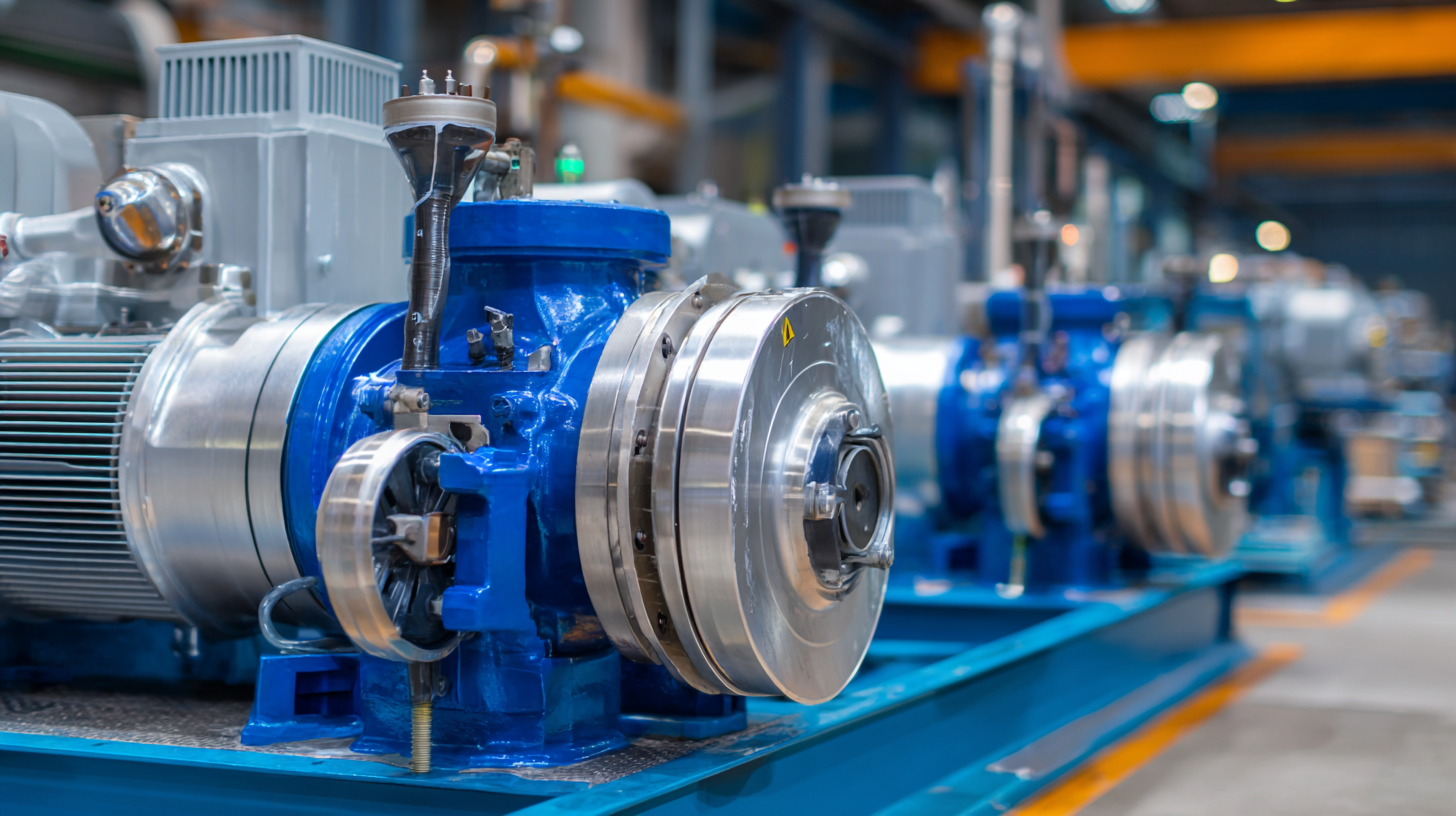

How to Select the Right Industrial Pump for Your Manufacturing Process

Selecting the right industrial pump is crucial for optimizing manufacturing processes. With a variety of pumps available, including centrifugal, diaphragm, and gear pumps, it's essential to assess your specific needs. Consider the type of fluid being pumped, its viscosity, and temperature. Additionally, the required flow rate and pressure will guide your choice. For instance, if you’re handling corrosive liquids, a pump made from resistant materials is necessary to prevent damage.

Tips: Always evaluate the total cost of ownership, which includes installation, maintenance, and energy consumption, when selecting a pump. Moreover, consult manufacturers for expert advice on compatibility with existing systems. Don’t overlook the importance of reliability in pump design, as downtime can lead to significant losses in productivity.

Another key consideration is the pump's efficiency and energy use. Look for models that offer variable speed options to adjust performance based on real-time demand. This can not only enhance efficiency but also save on operational costs. Regular maintenance and monitoring of pump performance can further ensure longevity and reliability, directly affecting your manufacturing output.

How to Ensure Optimal Pump Performance for Enhanced Efficiency

To ensure optimal pump performance in manufacturing industries, regular maintenance is crucial. Routine inspections can help identify wear and tear or any signs of potential failure before they escalate into significant issues. Implementing a preventive maintenance schedule not only extends the lifespan of the pumps but also guarantees that they operate at maximum efficiency. Monitoring fluid levels, checking for leaks, and calibrating pump settings are essential practices that contribute to maintaining high performance.

Moreover, the selection of the right pump for a specific application cannot be underestimated. Factors such as the type of fluid being transported, viscosity, and pumping distance must be carefully considered to choose a suitable pump. Regular training of personnel on pump operation and troubleshooting can enhance performance as well. By investing in both advanced technology and skilled operators, manufacturing industries can significantly improve productivity while minimizing downtime caused by pump-related issues.

How to Implement Preventive Maintenance for Industrial Pumps

Preventive maintenance for industrial pumps is crucial in ensuring uninterrupted operations in manufacturing industries. According to a report by the National Association of Manufacturers, nearly 30% of all manufacturing downtime is attributed to equipment failure. Implementing a structured maintenance plan can mitigate such risks, prolong the lifespan of pumps, and enhance overall productivity. Routine checks such as monitoring vibration levels, checking for leaks, and ensuring proper lubrication can significantly reduce the likelihood of unexpected breakdowns, which can be costly.

Industry studies suggest that preventive maintenance can reduce pump failure rates by up to 25% and lower maintenance costs by as much as 30%. Utilizing technologies such as predictive analytics and IoT devices can aid in monitoring the performance of pumps in real-time, allowing for timely interventions before a small issue turns into a significant problem. By fostering a proactive maintenance culture, manufacturing facilities can not only enhance efficiency but also optimize their operational costs, aligning with best practices outlined by the American Society of Mechanical Engineers (ASME).

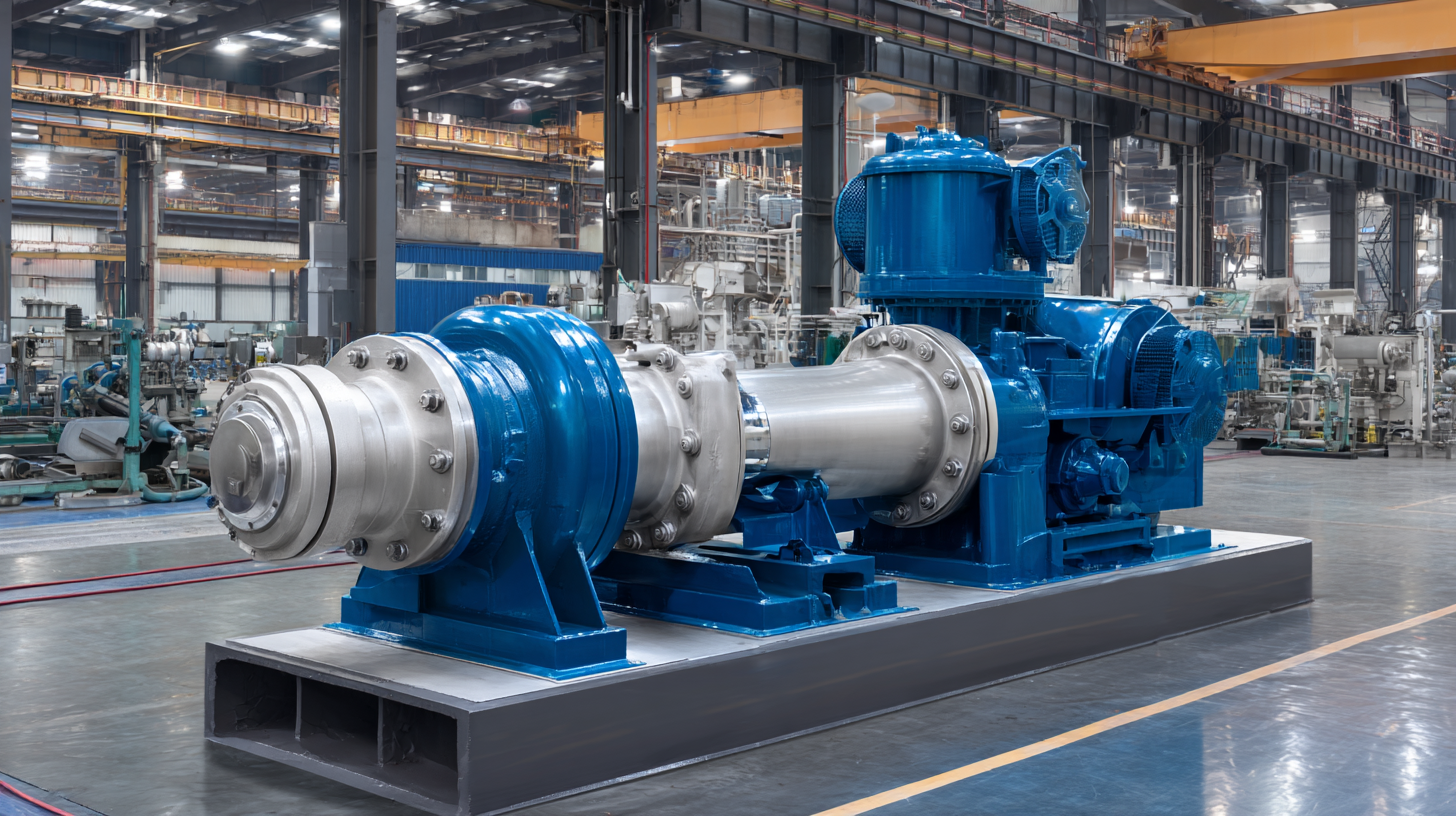

How to Integrate Pump Systems into Process Engineering Workflow

Incorporating pump systems into the process engineering workflow is paramount for enhancing operational efficiency in manufacturing industries. Recent advancements illustrate how integrating automated pump systems can optimize fluid management, reduce energy consumption, and streamline production processes. For example, the integration of smart technologies in geothermal energy systems not only showcases how pumps function as a critical component but also highlights the importance of data-driven decision-making in achieving enhanced efficiency solutions. Utilizing these technologies allows for real-time monitoring and control, which can lead to significant improvements in system performance.

Moreover, the move towards modular process plants emphasizes the need for standardization in pump system design and integration. As industry trends shift towards hybrid modular-monolithic process plants, standardized module type packages (MTPs) enable easier integration of pumps into new workflows. Reports indicate that this approach can lead to reduced engineering time by up to 30%, enhancing overall productivity and lowering operational costs. Additionally, leveraging AI-powered design tools not only facilitates better fluid power product development but also supports the integration of pump systems into cohesive engineering workflows, ensuring that manufacturing processes remain competitive in a rapidly evolving market landscape.

Industrial Pumps Efficiency in Manufacturing Process Engineering

How to Train Staff on Industrial Pump Operation and Safety Practices

Training staff on industrial pump operation and safety practices is crucial for any manufacturing facility that relies on these systems for efficient process engineering. A well-structured training program should begin with a solid understanding of the pump's components, including how they function within the manufacturing process. Hands-on demonstrations can greatly enhance comprehension, allowing staff to visualize workflows and troubleshoot common operational issues. Additionally, incorporating simulation-based training can prepare employees for real-world scenarios without the associated risks of live operation.

Safety practices should be an integral part of the training agenda. Operators must be well-versed in the potential hazards associated with industrial pumps, including the risk of electrical shocks, mechanical failures, and exposure to hazardous fluids. Regular safety drills and the use of personal protective equipment (PPE) ensure that employees develop a culture of safety that prioritizes well-being. Moreover, ongoing training sessions can help reinforce safety protocols and keep staff updated on new technologies and improved processes, ultimately fostering a more competent and safety-conscious workforce.

Related Posts

-

How to Choose the Right Jet Pump for Your Industrial Needs Based on Performance Data

-

Exploring Innovative Alternatives to Flo Jet Pumps for Efficient Fluid Management

-

7 Best Practices to Maximize Efficiency of Your Well Pressure Pump

-

7 Best Ways to Maximize Efficiency with Ultra Jet Pumps

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

How to Select the Right Fracking Pump for Your Oil and Gas Operations