2026 Top Downhole Jet Pump Innovations and Technologies Explained?

In the evolving landscape of energy extraction, the downhole jet pump technology stands out for its efficiency. Experts believe that innovations in this field can significantly enhance production rates. Dr. Sarah Lee, a prominent figure in the petroleum engineering sector, once stated, "The future of downhole jet pumps lies in refining their design for optimal performance."

Recent advancements focus on materials that withstand extreme conditions. These innovations aim to address common challenges, such as wear and tear, which often compromise performance. The emphasis is on creating pumps that not only perform effectively but also last longer. However, some designs still require re-evaluation.

Additionally, the integration of automation in downhole jet pumps is a thrilling trend. Yet, the industry faces hurdles. Not all companies have embraced these technologies, resulting in a gap between potential and actual performance. This inconsistency demands further exploration and thoughtful innovation, ensuring the full capabilities of downhole jet pumps are realized.

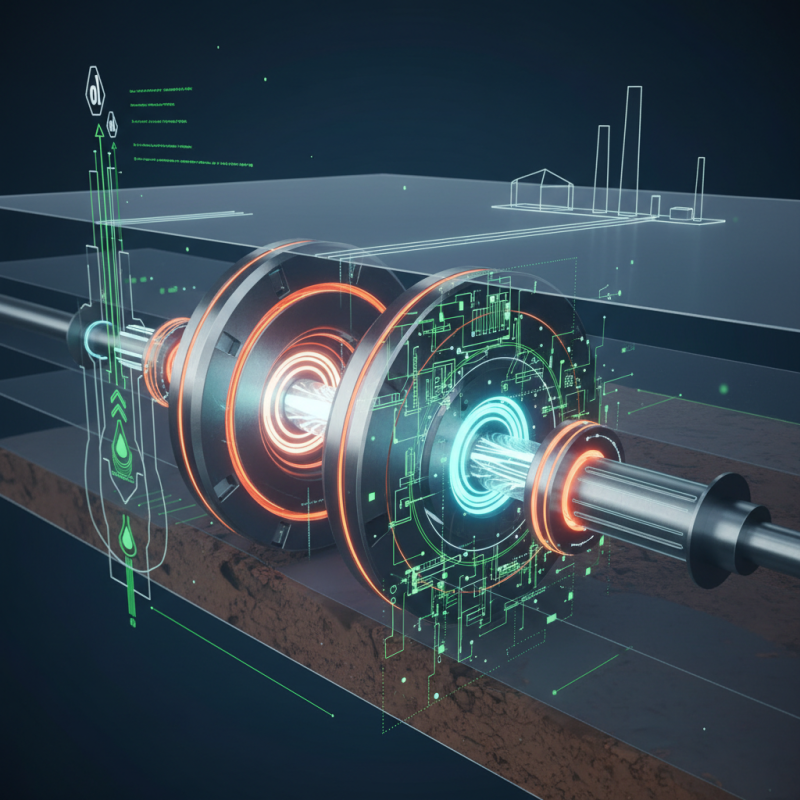

Overview of Downhole Jet Pump Technology Innovations

Downhole jet pump technology is evolving rapidly. This innovation plays a crucial role in the oil and gas industry. It's designed to lift fluids from depths efficiently. Recent advancements focus on improving performance and durability. These pumps are essential in wells with challenging conditions. They help to maximize production rates while minimizing downtime.

One exciting development is the integration of advanced materials. These materials offer superior resistance to corrosive fluids. They extend the lifespan of the pumps significantly. Another innovation involves the use of smart sensors. These sensors monitor performance in real time. This data-driven approach helps to identify issues before they escalate. Operators can analyze this information to improve operational efficiency.

Yet, challenges remain. The complexity of new technologies can lead to installation difficulties. Training for personnel can be time-consuming. In some cases, innovative solutions may have unforeseen complications. The balance between cutting-edge technology and reliable operation is crucial. Continuous reflection on these aspects ensures ongoing improvement in downhole jet pump systems.

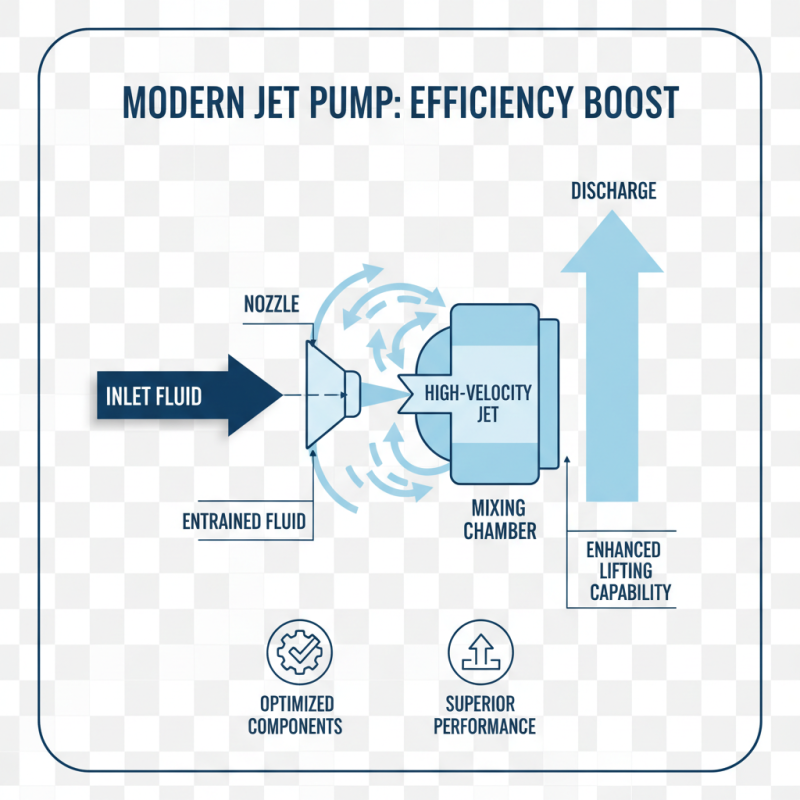

Key Components and Mechanisms of Modern Jet Pumps

Modern jet pumps are engineered with essential components that enhance their efficiency. The nozzle is pivotal. It creates a high-velocity jet of fluid, which pulls surrounding fluid into the pump. This clever design boosts the pump's lifting capability.

Another key element is the mixing chamber. Here, the jet fluid swirls, mixing with the incoming fluid. This process increases turbulence, which optimizes performance. However, imperfect mixing can lead to inefficiencies. Users may notice fluctuations in fluid output.

A check valve is also crucial. It prevents backflow, ensuring the pumped fluid remains consistent. Still, wear and tear can affect its reliability over time. Regular maintenance is necessary to avoid unexpected downtime. Understanding these components helps optimize jet pump performance effectively.

Advancements in Materials and Design for Jet Pump Efficiency

The advancements in materials for downhole jet pumps have led to significant efficiency gains. Recent studies show that using advanced composites instead of traditional metals can enhance durability and reduce wear. These materials exhibit a 30% increase in lifespan compared to standard options. This change is crucial, as pump failure can lead to costly downtime and repairs.

Design innovations are also central to improving jet pump performance. Engineers are experimenting with nozzle shapes that optimize fluid dynamics. These modifications can enhance the flow rate by up to 25%, boosting overall system efficiency. However, not every design is successful. Some prototypes have failed during testing, highlighting the need for careful analysis and iteration.

Moreover, the shift towards improved manufacturing techniques is noteworthy. 3D printing allows for customized designs that traditional methods cannot achieve. This flexibility leads to pumps that are better suited for unique environments. Yet, the technology is still evolving. There are challenges with material consistency and strength, which require ongoing research and development.

Impact of Smart Technology on Jet Pump Operation and Monitoring

The integration of smart technology in jet pump operation is transforming the industry. Advanced sensors and IoT devices are now standard. They enhance efficiency and provide real-time data. A recent report by the International Energy Agency states that smart technologies can improve pump efficiency by up to 30%. Such advancements allow operators to monitor performance closely and identify issues before they escalate.

Automation plays a key role in this evolution. Automated systems reduce manual intervention, which cuts down human error. However, the reliance on technology raises concerns. Over-dependence on automated systems can lead to a lack of skilled labor for troubleshooting. An industry survey found that 40% of operators worry about this skill gap. Maintaining a balance between technology and human expertise is crucial for operational resilience.

While smart technology enhances jet pump monitoring, challenges remain. Data overload is one issue. Technicians might struggle to analyze vast amounts of data. Effective training on data interpretation is essential. Without proper understanding, the benefits of smart technology could be diminished. A thoughtful approach to technology integration is vital to ensure long-term success in jet pump operations.

Future Trends and Emerging Technologies in Downhole Pump Systems

The landscape of downhole pump systems is changing rapidly. According to a recent market report, the global downhole pump market is expected to grow at a CAGR of 4.7% through 2026. Innovations are driving this growth. Emerging technologies like smart sensors and AI integration are becoming commonplace in pump systems. These advancements help optimize performance and reduce operational costs.

More companies are focusing on energy efficiency. Reports indicate that energy-efficient pumps can reduce costs by up to 30%. Advanced materials are also being tested. These materials offer greater durability and resistance to corrosion. However, their adoption isn’t straightforward. There are concerns about the long-term reliability of new materials in harsh environments.

Automation plays a crucial role in the future of downhole systems. Automated systems can operate around the clock, improving efficiency. Yet, this automation introduces complexities in maintenance. Data management is another issue. With many sensors collecting data, analyzing it can become overwhelming. The industry must find balance in implementing these technologies. The future is promising, but challenges remain.

Related Posts

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

5 Essential Tips to Maximize Efficiency with Ultra Jet Pumps in Your Industry

-

Ultimate Checklist for Selecting the Right Surface Jet Pump for Your Industrial Needs

-

Maximize Oilfield Jet Pump Efficiency with These 7 Essential Tips and Industry Insights

-

Ultimate Guide to Flow Jet Pump Tips for Efficient Pumping Solutions

-

10 Best Sucker Rod Pumps for Efficient Oil Extraction in 2023