2026 Best Downhole Jet Pump Options for Efficient Oil Extraction?

In recent years, downhole jet pump technology has gained significant traction in the oil extraction industry. As energy demands rise, exploration for efficient methods becomes essential. According to the Petroleum Technology Quarterly, nearly 70% of conventional pumping methods face efficiency limitations. This data underscores the importance of innovative solutions like downhole jet pumps.

Industry expert Dr. Sarah Evans stated, "Downhole jet pumps can enhance recovery rates while minimizing costs." This sentiment has driven companies to explore various models for improved performance. The design of downhole jet pumps allows them to operate effectively in harsher environments, extending their applicability in diverse oil fields.

However, challenges remain. Some current designs still struggle in certain formations, requiring continuous improvement. While the technology shows promise, not every rig can implement these pumps successfully. As companies evaluate their options for 2026, the right choice of downhole jet pump will be crucial for optimizing oil extraction processes.

Best Practices for Selecting Downhole Jet Pumps in 2026

When selecting downhole jet pumps in 2026, it's essential to focus on the specific needs of your oil extraction process. Factors such as depth, pressure, and flow rate significantly impact performance. Understanding these variables can help narrow down the best options for your operation.

Tip: Evaluate the well conditions. Know your well's depth and fluid composition. This data helps identify the right pump type. Additionally, consider the expected production rates. A mismatch can lead to inefficiencies or mechanical issues.

It's also important to analyze the pump's maintenance requirements. Some models may need more frequent checks. Others offer durability, needing less attention. Balancing efficiency and maintenance is crucial. It could help reduce downtime.

Tip: Consult with experts. They can provide insights into the latest technology trends. Sometimes, the newest model may not be the best choice for your situation. Look for products with proven reliability in similar wells. This can avoid costly mistakes and lead to better results.

Key Features of High-Efficiency Downhole Jet Pumps for Oil Extraction

In the search for efficient oil extraction, downhole jet pumps present a compelling solution. These pumps use high-pressure fluids to enhance oil flow from wells. Their design ensures maximum efficiency in converting energy into productive extraction. The key features to look for include high energy conversion rates and durable materials that resist corrosion.

When choosing a downhole jet pump, consider the operating conditions. Analyze the temperature and pressure requirements of your specific location. Pumps that can handle extreme conditions often provide better performance. Also, pay attention to maintenance requirements. Simpler designs are typically easier to maintain, leading to lower operational costs.

**Tips:** Regularly assess your pumping system. A sudden drop in efficiency may signal issues. Monitor fluid dynamics closely to ensure optimal performance. Always have a backup plan. This can save time and money during critical operations.

2026 Best Downhole Jet Pump Options for Efficient Oil Extraction

| Feature | Description | Efficiency Rating | Operating Depth (ft) | Max Flow Rate (bbl/day) |

|---|---|---|---|---|

| Input Pressure Range | 200 - 500 psi | 90% | 10,000 | 500 |

| Material | Corrosion-resistant alloy | 88% | 8,000 | 600 |

| Nozzle Design | Multi-venturi | 92% | 12,000 | 700 |

| Weight | 150 lbs | 85% | 9,000 | 550 |

| Compatibility | Water, Oil, Chemicals | 91% | 7,500 | 650 |

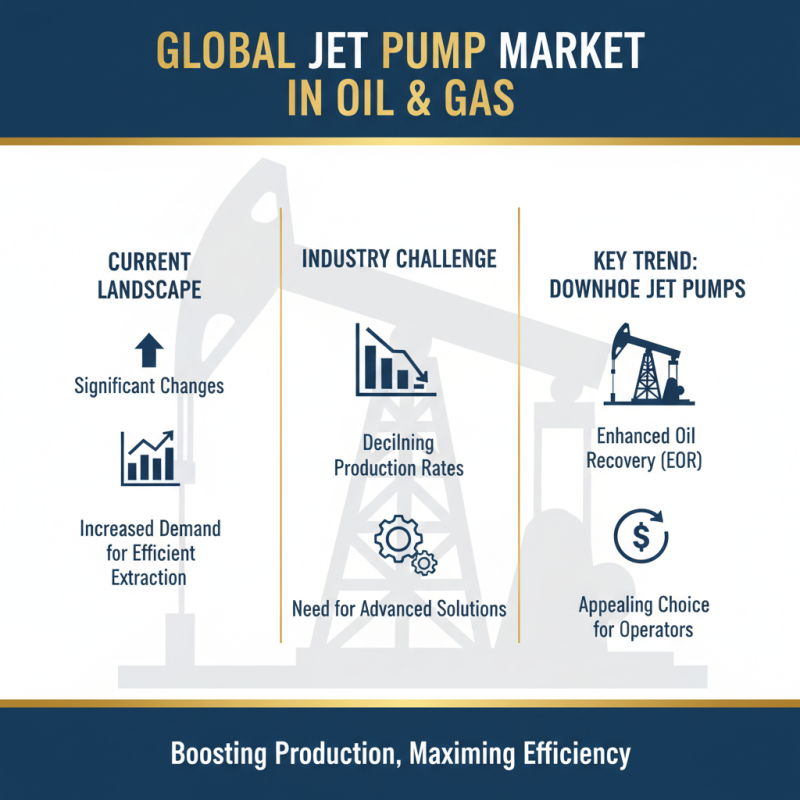

Market Overview: Demand and Supply Trends for Jet Pumps in Oil Industry

The jet pump market in the oil industry is currently experiencing significant changes. Demand for efficient extraction methods has surged. Many operators seek advanced solutions to tackle declining production rates. This trend has led to an increased interest in downhole jet pumps. Their ability to enhance oil recovery makes them an appealing choice.

Supply is adapting to meet this demand. Manufacturers explore innovative designs and materials. However, challenges remain. Not all jet pumps perform optimally in varying conditions. Factors like temperature and pressure affect efficiency. Some pumps struggle to maintain performance as reservoir conditions change over time.

The need for tailored solutions is critical. Operators must consider specific reservoir characteristics before selecting a pump. Collaborating with engineers is essential. They can provide insights on optimizing the setup. Investing time in understanding these aspects may lead to improved extraction rates. In a competitive market, hesitation can mean lost opportunities.

Performance Metrics: Evaluating Jet Pump Efficiency and Output Rates

The efficiency of downhole jet pumps is crucial for maximizing oil extraction in various conditions. Studies indicate that jet pumps can achieve output rates of 100 to 400 barrels per day. However, their performance can vastly differ based on the setup and well conditions.

Pump design plays a significant role, influencing hydraulic action and flow dynamics.

Evaluating jet pump efficiency involves examining factors like nozzle design and operating conditions. A well-optimized jet pump can deliver a 70% increase in production compared to traditional methods. Still, many operators encounter challenges, such as sand production and variations in reservoir fluid properties. These issues can complicate the output rates and lead to inefficiencies.

In terms of energy consumption, jet pumps typically use between 80 to 150 horsepower. Despite being efficient, proper maintenance remains a concern. Operators must routinely assess wear and tear on components. Neglecting these aspects can lead to significant drops in performance and output. Hence, continuous evaluation and adaptation are essential for ensuring these pumps meet the demands of modern oil extraction practices.

Technological Innovations in Downhole Jet Pumps for Enhanced Oil Recovery

The evolution of downhole jet pumps is transforming oil extraction efficiency. Recent technological advancements have enabled these pumps to enhance oil recovery rates significantly. A report by the International Energy Agency indicated that downhole jet pumps can improve production rates up to 30% in mature oil fields. This enhancement is crucial for maximizing output from existing wells.

Innovations such as variable jet nozzle technology and improved material selections are at the forefront. These advancements lead to better adaptability in challenging environments. Engineers now face the challenge of integrating these technologies without sacrificing reliability. Some new designs can struggle with wear over time, which raises concerns about long-term effectiveness.

Moreover, the implementation of smart technologies is becoming prevalent. Real-time data monitoring and automated adjustments optimize pump performance. Although the benefits are clear, high initial costs deter some operators. Balancing investment with potential recovery remains a delicate issue. Continuing advancements will demand both innovation and introspection from industry leaders.

2026 Best Downhole Jet Pump Options for Efficient Oil Extraction

This chart showcases the efficiency ratings of various downhole jet pump technologies based on their oil recovery rates. The data represents the estimated recovery efficiency (%), demonstrating the advancements in technology for enhanced oil extraction.

Related Posts

-

How to Choose the Right Jet Pump for Your Industrial Needs Based on Performance Data

-

Exploring Innovative Alternatives to Flo Jet Pumps for Efficient Fluid Management

-

Why Industrial Pumps Are Essential for Efficient Process Engineering in Manufacturing Industries

-

Understanding the Impact of Artificial Lift Pumps on Oil Extraction Efficiency

-

Exploring the Inner Workings and Advantages of Surface Jet Pumps in Modern Water Systems

-

The Ultimate Guide to Understanding the Versatility and Efficiency of Flo Jet Pumps in Modern Applications