What is a Water Jet Pump and How Does it Work?

The water jet pump is a marvel of modern engineering, efficiently harnessing the power of high-pressure water to transport fluids. Its diverse applications span industries, from mining to agriculture. A recent industry report by the International Pump Association indicates that the water jet pump market is projected to grow at a CAGR of 5.6% over the next five years. This growth highlights an increasing reliance on water jet technology.

Experts like Dr. Emily Hawthorne, a renowned figure in hydraulic engineering, emphasize the significance of this technology. She notes, "Water jet pumps offer unmatched versatility and efficiency in fluid transport." However, not every installation meets optimal performance standards. Many users overlook the importance of pump selection and maintenance. These oversights can lead to inefficiencies and mechanical failures.

Despite its advantages, the water jet pump also has limitations. For instance, high energy consumption can be a concern, especially in remote areas. Balancing energy usage with output remains an ongoing challenge. All these elements underline the importance of continuous improvement and innovation in the water jet pump field to fully realize its potential.

What is a Water Jet Pump?

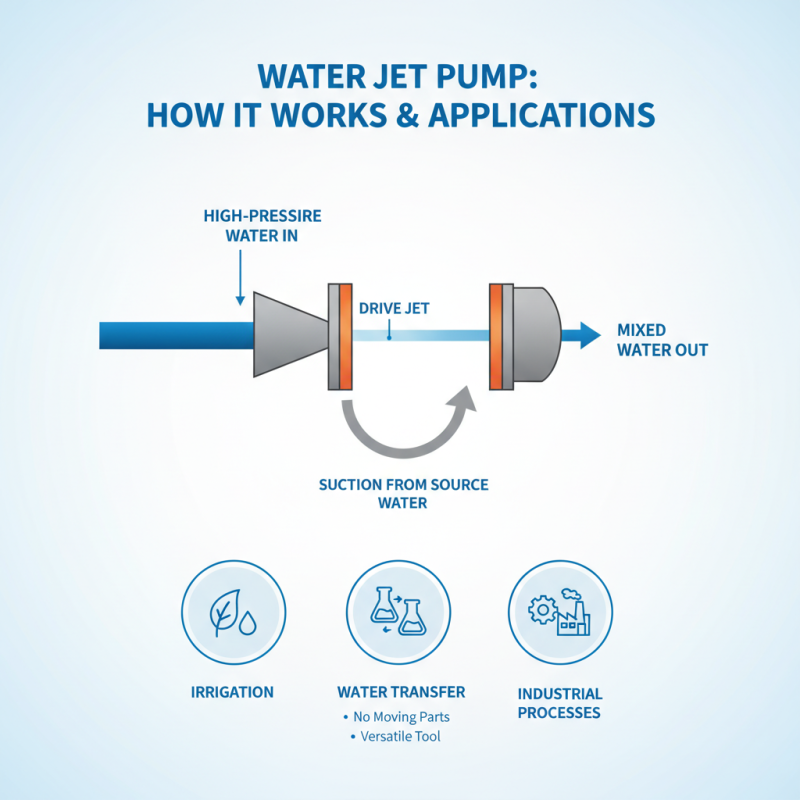

A water jet pump is a fascinating piece of machinery. It utilizes high-pressure water to drive a mixing jet that creates suction. This suction draws in water from a source, making it an effective tool for various applications. With its simple design, it can be used for irrigation, water transfer, and even in some industrial processes.

The main components of a water jet pump include the nozzle, mixing chamber, and diffuser. Water enters through the nozzle under high pressure, creating a high-speed jet. This jet mixes with water from the source in the mixing chamber. The combination produces a powerful flow that is easily transported. However, this effectiveness comes with limits. If the water source is too shallow, the pump may struggle to operate efficiently, leading to performance issues.

Operating a water jet pump can be a learning experience. Adjusting the pressure is crucial for optimal performance. If not set correctly, it may fail to draw in sufficient water. Observing these adjustments can reveal insights into the pump's behavior. It’s essential to adapt and understand its mechanics to harness its full potential. The simplicity of its operation can sometimes lead to overlooking significant details in maintenance and setup, resulting in frustration when it doesn’t work as expected.

Principle of Operation of Water Jet Pumps

Water jet pumps operate on a straightforward principle. They utilize high-pressure water to create a vacuum that draws more water into the system. This process is efficient and effective. According to industry reports, these pumps can achieve flow rates of up to 1,000 gallons per minute. This ability makes them essential in various applications, from irrigation to industrial uses.

The operation relies heavily on the Venturi effect. Water flows through a constricted section, creating low pressure. This low pressure draws additional water into the pump. However, efficiency can vary. Factors such as design and water quality impact performance. Some reports suggest that sediment can cause blockages. This results in reduced efficiency over time.

Water jet pumps are valued for their simplicity and power. They do not have moving parts, which minimizes maintenance needs. Yet, they are not always perfect. Performance can fluctuate based on the source water temperature. High temperatures can reduce the overall pumping efficiency. This unpredictability is a concern for engineers and operators alike. Balancing these variables is crucial for optimal operation.

Water Jet Pump Performance Factors

Components of a Water Jet Pump

Water jet pumps are fascinating devices that utilize fluid dynamics to create suction and move liquids. The heart of a water jet pump lies in its components. Understanding these parts can deepen our appreciation of this technology.

A water jet pump consists of a few critical components. The nozzle is essential, converting pressure energy into kinetic energy. This fast-moving fluid creates a low-pressure area, drawing in surrounding water. The mixing chamber comes next, where the high-velocity water mixes with the incoming fluid. This chamber is crucial; a poor design here can lead to inefficiencies in the pump's operation.

The pump's throat is another vital part. It narrows the flow, amplifying the thrust created by the jet. The tail end of the pump, often overlooked, helps with the transition of the mixed fluid back to normal pressure. Despite its simplicity, problems can arise if any component is not perfectly aligned. Small misconfigurations can lead to performance issues. Understanding these elements encourages careful consideration when designing or repairing water jet pumps.

Applications of Water Jet Pumps in Various Industries

Water jet pumps are versatile tools in many industries. Their unique ability to handle various fluids makes them invaluable in applications such as food processing, mining, and waste treatment. According to industry data, the global water jet cutting market is projected to reach $685 million by 2026, reflecting their growing importance.

In food processing, water jet pumps are crucial. They minimize waste by maximizing efficiency in cutting and mixing ingredients. In mining, these pumps help in mineral extraction with precision. The ability to cut through tough materials without damaging them is essential. Moreover, in wastewater treatment, high-pressure water jets remove sludge and debris effectively. This enhances the overall treatment process, making it more environmentally friendly.

Tips: Ensure regular maintenance on your water jet pumps to avoid downtime. Inspect seals and nozzles frequently to keep performance optimal. Moreover, train staff properly to handle these systems. Proper usage can extend the pump’s lifespan significantly. Any mistakes in operation may lead to inefficiencies, costing time and money.

What is a Water Jet Pump and How Does it Work? - Applications of Water Jet Pumps in Various Industries

| Industry | Application | Benefits | Water Jet Pump Type |

|---|---|---|---|

| Manufacturing | Material Cutting | High Precision, Versatility | Abrasive Water Jet Pump |

| Mining | Material Transport | Efficiency, Reduced Waste | Hydraulic Jet Pump |

| Construction | Groundwater Extraction | Reliable, Cost-Effective | Submersible Jet Pump |

| Food Processing | Cleaning and Sanitizing | Safe, Environmentally Friendly | Water Jet Cleaning Pump |

| Aerospace | Surface Finishing | High Tolerance, Smooth Surfaces | Ultra High Pressure Jet Pump |

Advantages and Limitations of Water Jet Pump Technology

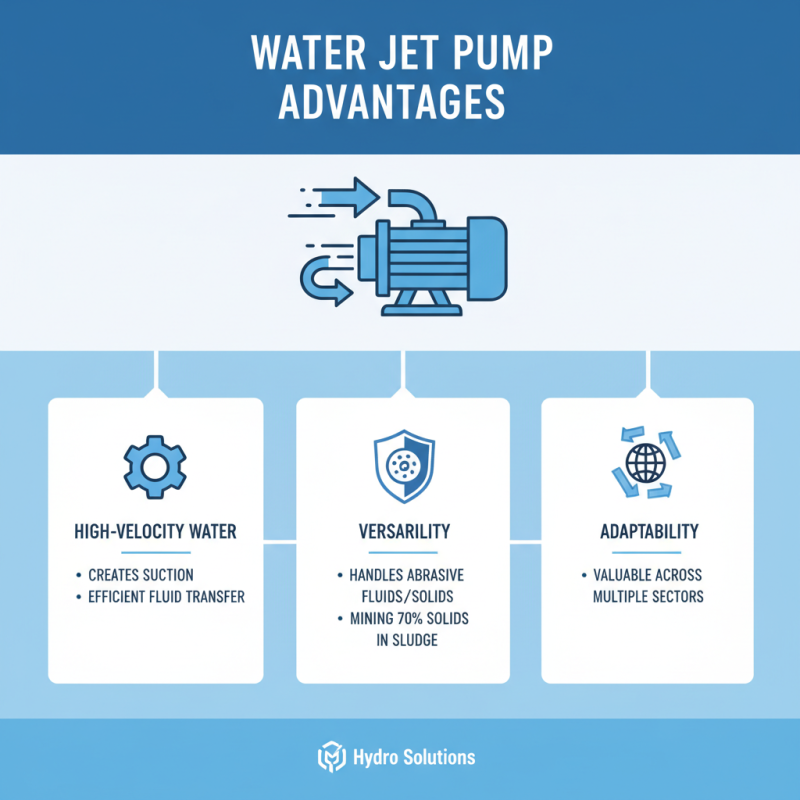

Water jet pumps are renowned for their ability to use high-velocity water to create suction. This principle provides an efficient solution for various applications. One major advantage of water jet pump technology lies in its versatility. These pumps can handle abrasive fluids and solids, making them ideal for industries such as mining and dredging. According to industry reports, water jet pumps can effectively manage up to 70% of the solid content in sludge. This adaptability is valuable across multiple sectors.

However, despite these advantages, there are limitations. Water jet pumps often require relatively higher energy inputs compared to other types of pumps. This can impact operational costs. In fact, studies suggest that energy efficiency for water jet pumps averages around 50%, which raises concerns for long-term sustainability. Additionally, using water as a fluid can be less effective in environments with low water availability. Such conditions may lead to inefficiencies and increased risks of pump failure.

Moreover, maintenance can be a challenge. While these pumps are robust, they may encounter wear due to the abrasive materials they handle. Regular maintenance is essential to ensure reliability. Failure to address wear and tear can lead to unexpected downtimes. This factor can significantly affect operational efficiency and costs. Overall, while water jet pumps provide unique advantages, understanding their limitations is crucial for optimal usage.

Related Posts

-

2026 Best Water Jet Pump Reviews for Your Needs?

-

What is a Water Jet Pump and How Does It Work in 2026?

-

How to Choose the Best Water Jet Pump for Your Needs?

-

Exploring Market Trends: Ultra Jet Pumps at the 138th Canton Fair 2025 in China

-

2026 How to Choose the Right Surface Jet Pump for Your Needs?

-

How to Choose the Right Ultra Jet Pump for Your Needs?